INTRODUCTION

Industrial Automation in manufacturing means the use of intelligent machinery to improve the manufacturing process and decreasing human intervention, which involves the application of various control systems and helps enable operating equipment to work on their own at the best speed, endurance, and precision.

This automation can be achieved by several different means which include mechanical, electrical, electronic, hydraulic, pneumatic, and computers. This automation also brings a series of benefits as well like leaner operations which will require less energy, less material, and reduced labor waste, which can further improve the quality, accuracy, and precision. But will these benefit there are also some downsides with one of the major one being high costs of R&D and the installation of equipment.

TYPES OF MANUFACTURING AUTOMATION

Automation helps in reducing the work performed by humans and has become associated with electromechanical systems that are programmed to perform many types of processes.

Even though it is said that automation may not be for every manufacturer, but they may find benefit in it as these are divided into three categories:

- Fixed Automation/Hard Automation: It means the process or assembly that is dictated by programmed commands which are relatively difficult to accommodate changes in the product design.

- Programmable Automation: It is mostly used to manufacture products in batches which allows for customization and frequent changes throughout the manufacturing process. New programs can be prepared and entered into the hardware to produce new products anytime.

- Flexible Automation: Utilization of multiple tools linked by a material handling system. This automation can produce a variety of parts with no time lost for change from anyone part style to the next, the same goes for reprogramming the system or altering the physical set up.

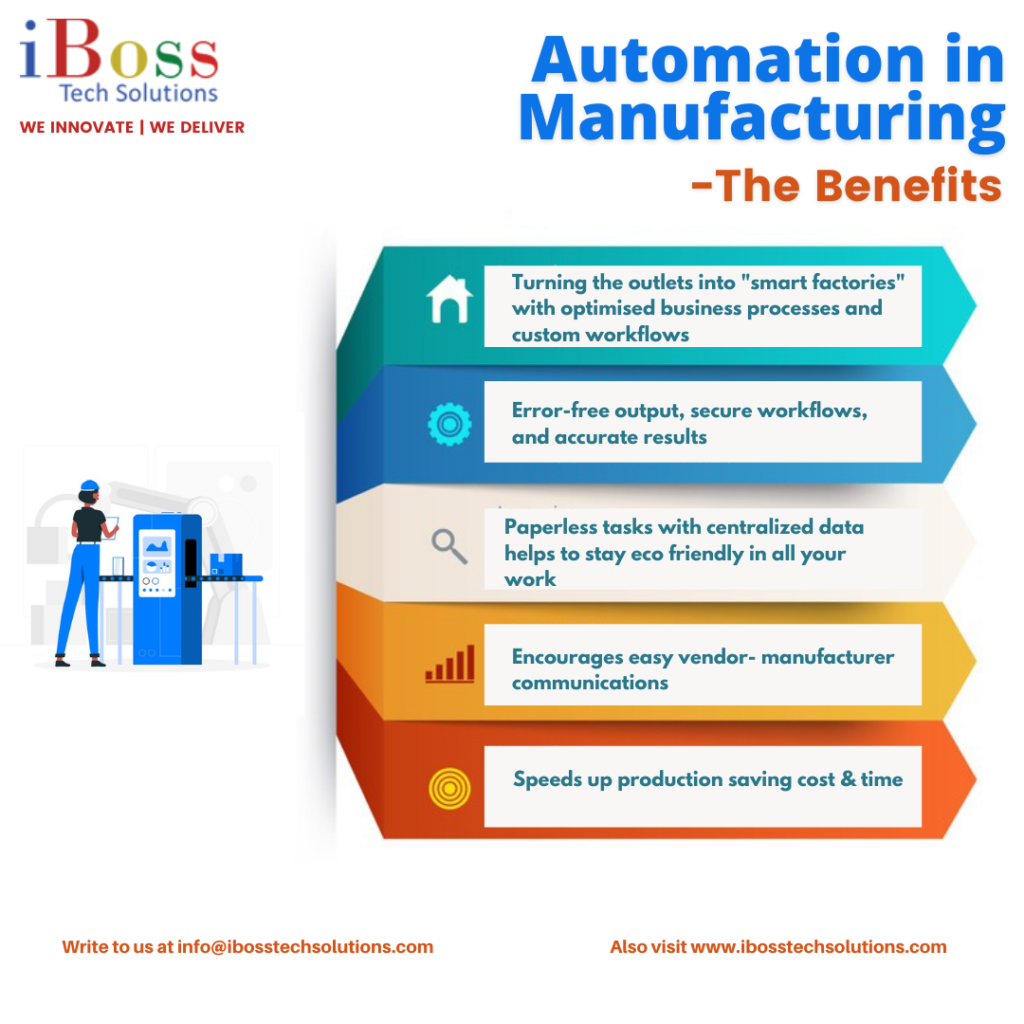

ADVANTAGES OF INDUSTRIAL AUTOMATION

Industrial Automation has a lot of advantages that can help the manufacturers in a lot of ways and can help in reducing healthcare costs, paid leaves/holidays with a human operator. The maintenance cost is associated with machinery that can be used for industrial automation and in case the computer fails the maintenance engineers can replace it.

More advantages for the same are as followed:

- High Productivity: Companies need to hire thousands of workers to ensure that the maximum hours are reached, and the plant must be closed for maintenance and holidays. But with the help of machines and automation will allow manufacturers to run their plants all the time which would further improve the productivity of the country.

- High Quality: Automating tasks alleviates the error that is associated with a human being and unlike humans, it does not involve any fatigue. Thus, ensuring uniform quality manufacturing at different times.

- High Flexibility: Human Operators require training if a new task needs to be added to the assembly line. But with robot’s automation can easily just be added to their code and they will perform tasks accordingly making the manufacturing process more flexible.

- High Safety: Industrial Automation can increase the safety of the employees in the production line by deploying robots to handle hazardous and dangerous conditions.

- High Information Accuracy: Automating the data collection process allows you to collect key production information, improve data accuracy, and reduction of data collection costs, which also provides the facts to make the right decisions when it comes to reducing waste and improving your processes.

CURRENT STATE OF INDUSTRIAL AUTOMATION

High precision work in factories especially the automobile sector where processes such as car assembly lines are automated and taken over by industrial robots. These robots have a high computing capability which has helped in improving vision systems and increasing the operational degrees of freedom.

These robots, however, are limited to operating in highly structured environments that still need to be controlled by humans. These machines are also too specialized and inflexible for use of small and medium industries. Thus, making them suitable for long production runs and large manufacturers.

With the rapid development of microcomputer and software technologies, automation in manufacturing currently depends on the capabilities of the computers and the software to automate, optimize, and integrate the various components of the manufacturing system. All this dependence has given Computer Integrated Manufacturing the name for automation in manufacturing.

CONCLUSION

Industrial robots of the future will be multi-functional so that the machine can be put to several different uses and will have the capabilities to be associated with human workers like the ability to make decisions and to work autonomously. They will also have self-diagnostic and predictive maintenance capabilities.

All this in the future will also lead to more efficient factories with better utilization of energy, raw material, and human resources. There is also a belief that all this automation will lead to widespread unemployment, but from the experience so far it is not the case; rather it has created more jobs allowing humans and robots to work together and be more efficient and productive.

Industrial Automation is now being more accepted by people in all the industries even the manufacturing industry this includes a lot of benefits, such as increased productivity, quality, and safety at low costs.

HOW CAN iBOSS HELP

iBoss has been providing solutions for over 12 years, focusing on four major pillars of digital transformation being Automation & AI, Digitization & Digitalization, Rapid Application Development, Cloud, and Infrastructure Management. Leverage iBoss’s core capabilities to evolve on your digital transformation journey.

iBoss can help businesses to adapt to Smart Industry Solutions and make the work environment more efficient. Make document management across the organization less complex with easy to access documents from any device, cloud-based storage, make approval online using workflows, develop a quick mobile application, while ensuring user roles-based access. Digitize manual processes into digital processes now with iBoss.